The Dry Irish Stout is really quite a simple recipe: British pale malt as the base, flaked barley for that creamy mouthfeel, and roasted (unmalted) barley for the color and roasty bitter flavor. No crystal malt here! Save that stuff for your Oatmeal and Imperial Stouts. Also, roasted barley (or black barley, or black roasted barley) and black malt (or black patent malt) are not the same thing! They're both made from barley and they're both black, but that's where the similarity ends. Roasted barley is unmalted, and that means that the starch is entirely unconverted. Black malt is made from grain that is malted until it is fully modified. Then it is heated so high that it actually has to be closely monitored to make sure it doesn't catch fire. As a result, while roasted barley imparts very bitter roasted flavors (think coffee and dark chocolate), black malt can also contribute burnt, ashy, and potentially acrid flavors. It has its place, but not in this beer. Unfortunately, when I went to my LHBS to buy roasted barley, they only had US roasted barley which is only roasted to 300°L, instead of the 550°L that UK roasted barley is. I had a little bit of UK roasted barley lying around, so I subbed in US roasted barley for the remainder and then adjusted the color with Carafa III until it was right. I'm not sure exactly what effect this will have on the flavor, but I guess that's the fun in homebrewing, right?

As for hops, a single bittering addition is all we need. For me, it's going to be a bit of a freezer cleaner, because I have a few packages of hop pellets that are just sitting in there. Fortunately, they are mostly English cultivars (Fuggle and Golding). Willamette is just the American version of Fuggle. So we're good there. I made up the remainder of the IBUs with a package of Northern Brewer. It doesn't really matter though, we just want those alpha acids. There might be a bit more of a vegetal note from the fact that we're using 5 ounces of pellets instead of just an ounce or two of super-high alpha hops (e.g. Apollo, Columbus, Summit), but I'm pretty sure that's no big deal.

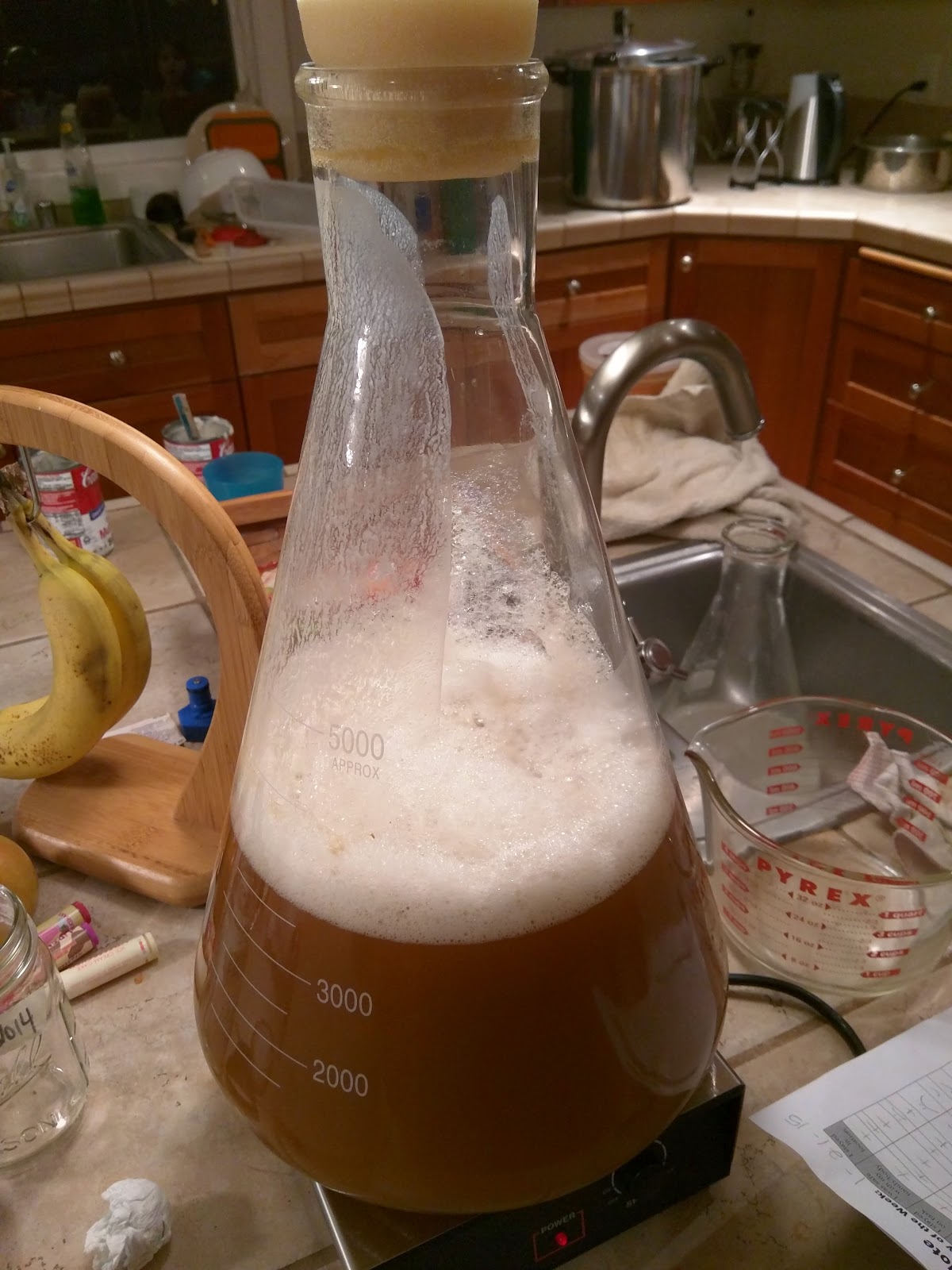

The yeast is a no-brainer: Wyeast 1084 Irish Ale. I had some saved in a mason jar in my refrigerator from last July. So I woke it up and propagated with a two-step starter. I'll need about 400 billion cells to make sure this finishes low enough—Wyeast 1084 is known for quitting early.

I sometimes encounter people who seem to think that Guinness (a Dry Irish Stout) is high in alcohol, really heavy, and high in calories. They are often surprised to hear that the opposite is true. Guinness Draught is 4.0% ABV and a 12-ounce serving has 125 calories. That's less alcohol and only 15 calories more than Bud Light.

Your Mom

Batch size: 12 gallons

Expected efficiency: 75%

Target OG: 1.047

Target FG: 1.013

Color: 34 SRM

Grist:

Batch size: 12 gallons

Expected efficiency: 75%

Target OG: 1.047

Target FG: 1.013

Color: 34 SRM

Grist:

- 14# Thomas Fawcett & Sons Maris Otter Pale Malt

- 4# Flaked Barley

- 1# 11.5 oz. US Roasted Barley (300°L)

- 12 oz. Carafa III

- 4.5 oz. UK Roasted Barley (550°L)

- Protein - 126°F for 15'

- Saccharification - 150°F for 60'

- Mash out - 169°F for 10'

- 2 oz. UK Fuggle (pellets, 4.5% aa)

- 1 oz. UK Golding (pellets, 5.1% aa)

- 1 oz. Willamette (pellets, 5.0% aa)

- 1 oz. Northern Brewer (pellets, 7.8% aa) at 60' to a combined 41 IBU

- Chill to 65°F, O2, pitch Wyeast 1084 Irish Ale

- Hold at 65°F until fermentation is almost complete, then free-rise to 70°F for a few days to reduce diacetyl

- Crash cool to 35°F, add Biofine Clear, and keg

|

| A very fine crush. |

|

| Mashing in. Starting to look good already. |

The boil was uneventful. Five ounces of hops is a lot, so I made sure to stir pretty well. At the beginning of the boil, with 5 oz. of hops getting thrown in, the hop aroma was pretty strong. This beer isn't supposed to have any real hop aroma or flavor—just bitterness. As the boil went on, I continued to make olfactory observations, and sure enough, the volatile hop aromas (and, I assume, flavors) dissipated as expected. Part of me was happy because that's what I was going for. But part of me mourned the aromatics as they were vented out of my brewery. A lone, brave Whirlfloc tablet went in at 15'. Godspeed, little guy! I chilled it to about 75°F on its way out of the kettle, and then got it down the last ten degrees in a chest freezer over the next hour. Then I hit it with pure O2 and pitched the yeast.

|

| Now we wait. |

|

| Another generation of the yeast cycle begins. |

No comments:

Post a Comment